Heath Pipeline Services

Heath Pipeline Services Pty Ltd (previously known as Heath Consultants) has served gas and oil providers located in Australia, New Zealand and Papua New Guinea, for more than 40 years. Today we focus our offering across three core pillars …

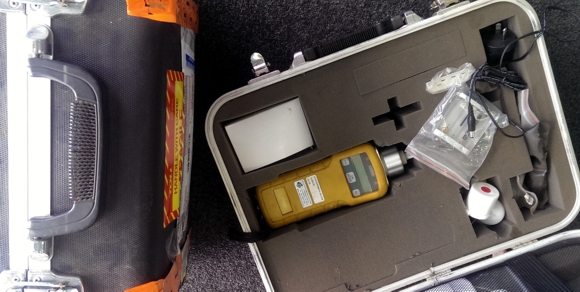

EQUIPMENT- HIRE, LEASE, PURCHASE

We are proud to be the distributor of choice for world leading brands, delivering increased accuracy, safety and productivity to our clients.

- Our clients can HIRE items from a fleet of specialist gas leak detection equipment

- Our clients can LEASE equipment from us

Our clients can PURCHASE equipment from us. We offer competitive prices, calculated daily. We frequently source items from overseas on short notice for our clients and manage all aspects of the supply chain. This may include negotiation of design specifications or even the development of prototypes.

FIELD SERVICES

We provide in-field and corporate consultancy services. Operating under a sustainability framework, designed to map to client requirements, we provide the below services:

- Calibration and repair of GMI and Heath gas leak detectors

- F-class testing

- Fugitive emissions detection

- Gas leak surveys – Above and below ground pipelines (associated infrastructure), well heads, gathering systems, and compounds i.e. compression and sales stations

- Hot tapping & line stopping

- Pipe cleaning

- Right of Way survey (ROW)

- Valve servicing

TRAINING

Our qualified trainers deliver bespoke courses. We also host international trainers and offer specialist ‘schools’.

- 2017 – ValvePro® courses to be held throughout Australia at various locations. 27 October to 14 November, 2017. Click here to learn more.

- PAST EVENT – ADVANCED LEAK DETECTION PROGRAM for June/July 2016. Click here to learn more.

We partner with SIMTARS – training, research and testing (Department of Natural Resources and Mines) and recommend their industry courses to our clients. When we sell equipment, we often include SIMTARS training as standard, ensuring that our clients receive recognised training solutions for the best possible results in the field.

Any training that we provide or recommend focuses on manufacturer guidelines, industry standards and overarching legislation, for the accurate, productive and safe use of the products we distribute.